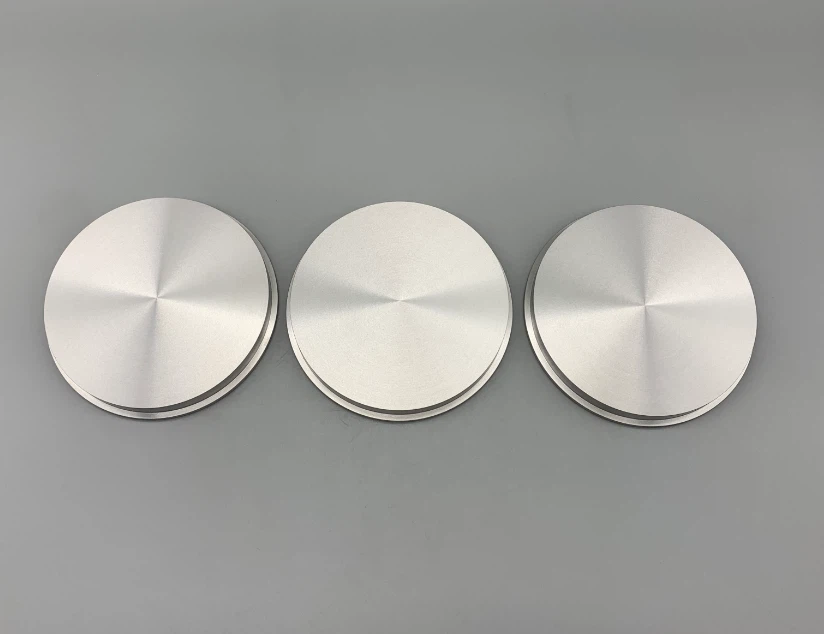

Products Description

1.Definition and characteristics of titanium target

Titanium targets are specialised materials mainly used in Physical Vapour Deposition (PVD) and Magnetron Sputtering techniques. Of these, PVD technology is widely used in the production of advanced coatings, while magnetron sputtering is commonly used in the manufacturing of semiconductor chips and electronic components. Titanium targets are finely manufactured with pure titanium or titanium alloys as the main component. Its unique benefits include extremely high hardness and density, as well as excellent corrosion resistance, which makes it stable in a variety of environments. In addition, titanium targets have good thermal conductivity and high purity, providing excellent performance for sputtering thin film technology.

Titanium target is a high-purity titanium or titanium alloy slab material made by vacuum melting - investment casting process. Its most significant characteristics are high purity and excellent densification. The density of high quality titanium target can reach more than 99.5%, and the impurity elements are very low, such as Fe, Si, O, N, H and other elements are less than 100 ppm, which makes titanium target in the physical properties and chemical properties are far more than the ordinary industrial pure titanium.

In addition, the titanium target has excellent homogeneity. During the preparation process, multiple melting and quenching treatments are used to effectively improve the organisational homogeneity of the titanium target. The surface of the target is smooth and clean, and the internal organisation is dense and fine-grained, which ensures the uniformity of the deposited layer. Titanium target also has excellent thermal conductivity and small thermal stress, so that it is not easy to produce cracks, can withstand high-power sputtering or arc evaporation process. In addition, the high mechanical strength of titanium targets effectively increases their service life and reduces target losses, thus improving their overall performance and value.

2.Preparation process of titanium target

Raw material selection:As titanium targets are mainly used in the coating process, it is common to select 99.99% pure titanium blocks as the raw material. A good raw material should be free from obvious appearance defects such as oxidation, impurities, cracks, etc. to ensure that the raw material is of uniform texture and high purity.

Melting:In the melting stage, a vacuum arc melting furnace is used to heat the titanium raw material to over 1,668 degrees Celsius (the melting point of titanium) to completely melt the raw material. In order to prevent the mixing of gaseous impurities, the entire process needs to be carried out in a high vacuum environment. Some specific applications may require a gas guard (e.g. argon) to protect the target from oxidation.

Forging:

In this stage, liquid titanium is poured into a mould to cool and solidify, and then pressed with uniform force using a hydraulic press. During the forging process, there are often heating and holding steps because a certain temperature must be maintained to keep the material ductile.

Roughing:

At this stage, the target is first machined to the applicable shape and size. This may include the use of a CNC lathe or CNC milling machine to precisely cut and shape the target.

Heat Treatment:

In most cases, targets require heat treatment, such as solution treatment or annealing, in the range of 800-1000°C for several hours. The purpose of these treatments is to improve the microstructure of the material and enhance its strength and toughness.

Surface finishing:

After the above treatment, the target needs to undergo surface finishing, such as grinding and polishing. Firstly, a large area is probably ground with abrasive paper, and then the coarseness of the abrasive paper is gradually reduced for fine grinding.

Quality inspection:

At this stage, titanium targets are subjected to a series of quality checks, including UT measurements (ultrasonic flaw detection), XRD examination (X-ray diffraction) to confirm the structure, and determination of the chemical purity by ICP-AES or LECO analyses, among others.

Boxing and Shipping: Finally, the titanium target needs to be encapsulated in a dust-free environment, usually using vacuum packaging, to maintain the purity of the product. They are then placed in specially designed boxes to protect the product from damage during transport.

Hot Tags: gr2 titanium target, China gr2 titanium target manufacturers, suppliers, factory, Titanium Hex Socket Head Cap Screw, titanium and titanium alloy, Zr1 Zirconium Plate, Titanium Round Head Cross Screw, Zr3 Zirconium Rod, Smooth Titanium Rod